Optical communication knowledge sharing, joining hands to become an expert in the field of optical communication network detection.

The splicer electrode is one of the important part of the fusion splicer which has a certain working life. It is the important comsumable material.However, when the electrode reaches a certain discharge number(maybe around 5000times), its discharge stability will be affected, and the discharge stability is an important factor in the replacement cycle.

The causes and hazards of worn electrode

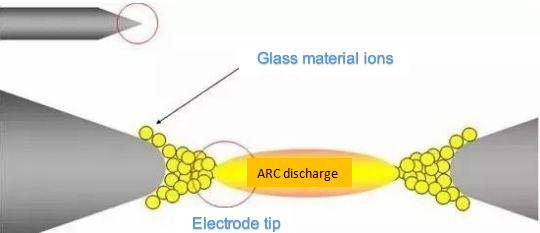

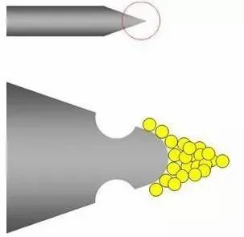

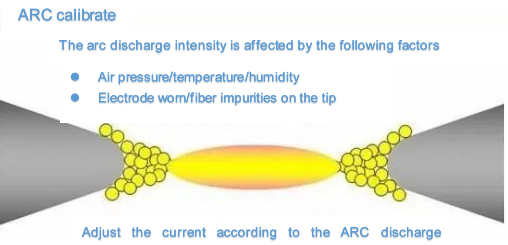

The tip of the new electrode is relatively clean, and its metal material is also very hard, which will not be worn by external forces. However, due to the long-term high-temperature and high-voltage discharge, the tip of electrode will wear slowly and aging is inevitable. At high temperature, the glass material ions of the optical fiber will diffuse, and some impurities will be adsorbed on the tip of the electrode. For a long time, it will be found that there is a white material accumulation at the tip of the electrode, which will form non-conductive insulating impurities, resulting in poor discharge stability of the electrode

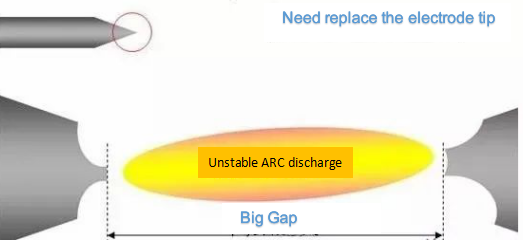

The accumulation of white impurities at the tip of the electrode rod results in no discharge at the original discharge position of the electrode tip. On the contrary, discharge splicing is carried out from the area behind the tip, which will further accelerate the aging wear rate of the electrode tip and make it irregular.

As mentioned above, the arc triggered by two stable tips will become extremely unstable, which may cause unstable discharge and offset of discharge position on the fusion splicer, which can not provide stable electric heat source for optical fiber fusion, and the final splicing loss will not be ideal.

In order to ensure the splicing quality and make the service life of the electrode close to the ideal value, it is necessary to maintain the electrode regularly. It is recommended to clean the electrode with cotton swab dipped in anhydrous alcohol.

When the fusion splicer indicates that the electrode needs to be replaced, the new electrode should be replaced in time. The first choice for replacement is to choose the original manufacturer, which has a higher adaptability to the internal power components of the fusion splicer, so as to avoid overload damage to other parts.

It is undeniable that the wear of electrode is affected by many external factors, such as air humidity, temperature, air pressure and optical fiber material. Therefore, the service life of electrode will be different in different working environment, and the replacement cycle needs to be judged by the user according to the actual situation.

Tip: Regular ARC calibrate is also helpful to prolong the life of electrode and improve the quality of splicing.