Generally speaking, cladding alignment splicer equip with four motors, ZL, ZR, X and Y motors. However for core-alignment splicer, there are two more motors, ZL, ZR, X, Y, FocusX and FocusY. FocusX and FocusY motors make the splicer the true core-alignment splicer.

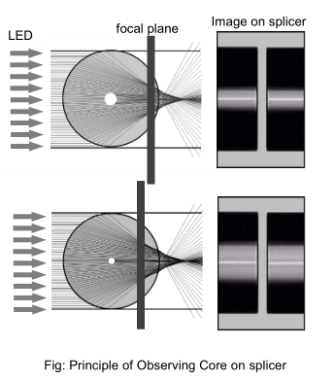

The following figure shows the principle why 6 motors splicer can observe fiber core.

LED illumination comes from left side. We can regard it as parallel beam. Because of the refractive index difference between cladding and core, a part of the beam condenses. Setting focal plane to the adequate position, we can catch the condensed beam. We can see it as a white line in the fiber image on the splicer.

Upper figure shows about standard SM fiber. Lower figure shows about smaller core size fiber. You can see the difference of adequate focal planes. Thus, the adequate focal plane depends on the core size. Focus motor leads the focal plane to the adequate one according to fiber type.

Recently, many types of fibers are in the market. For example, BIF, bend insensitive fibers, G.654, core size is different from conventional standard SM fiber. To splice such fibers with low loss, to set focal plane precisely is very important.

To be a true “core alignment splicer”, the splicer must equip 6 motors is necessary, ZL, ZR, X, Y and FocusX, FocusY.